Interview | ZKTeco Europe Prioritizes Customer Experience: RMA, Quality & Production

ZKTeco Europe is committed to providing its customers with seamless services and operations. To better understand our operations, quality control and the recent improvements to the RMA process, an important part of our after-sales services, we spoke with Jorge Serna, RMA Manager, and Nacho Meneses, Workshop Manager.

Jorge Serna, RMA Manager

Nacho Meneses, Workshop Manager

In the photo left to right: Óscar Martínez Production specialist, Lane Vin RMA specialist, Jorge Serna RMA Manager, Nacho Meneses Quality & Production Manager and Jesús Cabrero Quality specialist.

Enhanced RMA Process for a smoother experience

We have made significant improvements to our RMA process to ensure a faster and more efficient experience for our customers. Here is what you can expect:

- Dedicated Teams: Our RMA team has been restructured with specialized teams for repairs and quality control. This ensures faster turnaround times and expert handling.

- Extended Warranty: We are confident in our devices and service, so we have extended the repair warranty period to 6 months. This gives you added peace of mind and reinforces our commitment to quality.

- Optimized Online Support: We have redesigned the online support platform to streamline the return process. This allows for faster issue resolution and a more user-friendly experience.

- Rigorous Approval Process: Stricter return request approvals ensure swift and efficient processing, minimizing delays and maximizing your satisfaction.

A conversation with ZKTeco Europe's Operations and After-Sales Experts

Thank you, Jorge and Nacho, for taking the time to speak with us today. We are excited to learn more about the recent improvements to ZKTeco Europe's operations and after-sales service. Let us start by diving into quality control.

Nacho, as Workshop Manager, can you tell us about the mission of the workshop unit and quality control plays in ZKTeco Europe's operations?

Nacho Meneses (Workshop Manager): Absolutely. Quality control is paramount at ZKTeco Europe. We have a dedicated team responsible for meticulously inspecting every product. This ensures that only the highest quality devices reach our customers.

Quality control procedures are implemented upon receiving products, not before shipping, from our factory before the material is placed in its designated warehouse locations. At this stage, if any issues are detected, they are passed on to in-house production for bulk rectification.

Can you tell us about your role and the main mission of the workshop?

Nacho Meneses: As the Workshop Manager, my primary responsibility is to ensure that all products arriving at our warehouse are transformed, modified, or adapted according to customer requirements. Our mission is to satisfy customer demand for ZKTeco products by ensuring that every item is properly modified and ready for immediate use. We also aim to minimize errors and failures to reduce the impact on after-sales service and returns.

Excellent. Now, let us turn to Jorge. Can you tell us about your role and the mission of the RMA after-sales department?

Jorge Serna (RMA Manager): Of course. As the RMA After Sales Manager, my role involves managing the repair, and after-sales service processes for ZKTeco products. Our mission is to ensure that our after-sales service processes are efficient and effective. We handle product repairs, and replacements to maintain high customer satisfaction.

In addition to inspecting new products, how does your team approach quality control for returned items?

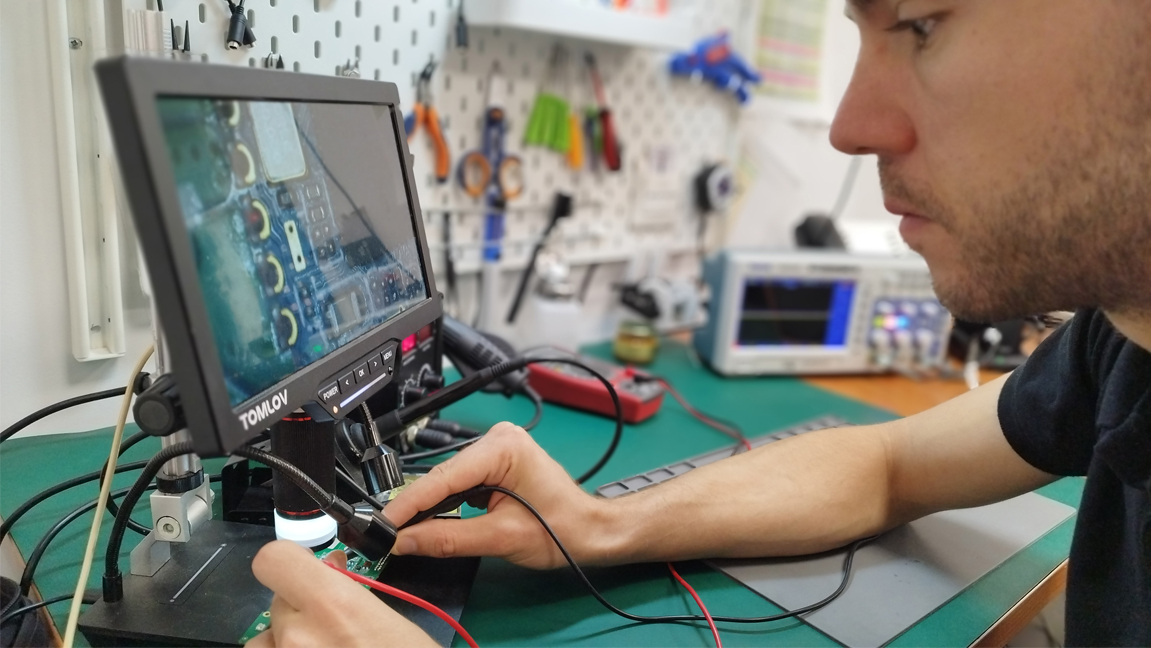

Nacho Meneses: Our RMA process integrates seamlessly with quality control. Each returned device undergoes a rigorous inspection and testing process by our specialized technicians. This allows us to identify the root cause of any issues and ensure a proper repair before the device is returned to the customer.

Excellent. Now, let us shift gears and talk about operations. Jorge, as RMA Manager, can you elaborate on how the recent restructuring of the RMA team has impacted overall efficiency?

Jorge Serna: Of course. We have recently divided our RMA team into specialized units focusing on repairs and quality control. This restructuring allows us to allocate resources more efficiently and ensure a higher standard of service for our customers.

That sounds like a positive step forward. Nacho, as the Workshop Manager, how do you see these changes impacting the repair process?

Nacho Meneses: The restructuring has streamlined our operations. With dedicated teams for repairs and quality control, we can now prioritize tasks more effectively and ensure that each device undergoes thorough inspection and testing before being returned to the customer.

The extension of the repair warranty period to 6 months is another welcome announcement. What led to this decision?

Jorge Serna: We have full confidence in the reliability of our devices and the expertise of our repair team. By extending the warranty, we aim to demonstrate our commitment to providing long-term value to our customers and ensuring their complete peace of mind.

Nacho, can you elaborate on the changes made to the customer return workflow?

Nacho Meneses: Absolutely. We have redesigned and optimized the return process for a more streamlined experience. Customers can now conveniently submit their return requests through our online support platform. This platform also facilitates a rigorous approval process, ensuring swift resolution and minimizing delays for our customers.

And Jorge, what can customers expect in terms of transparency and efficiency with these new processes in place?

Jorge Serna: With clearer processes and dedicated teams overseeing each step, customers can expect improved efficiency and transparency throughout the process. We aim to provide a smoother and more satisfying after-sales experience for everyone.

Thank you both for sharing these valuable insights. Before we wrap up, let us address a common question customers might have: how can they track the status of their returns?

Nacho Meneses: We prioritize transparency throughout the Quality Control process. Customers will receive automated notifications at each stage, keeping them informed of any updates on their return. Additionally, our dedicated customer service team is always available to answer any questions or provide further assistance.

It seems like both departments are heavily involved in ensuring product quality and customer satisfaction. How do you collaborate with the Quality Control area?

Nacho Meneses: We work closely with the Quality Control and Production team to ensure all products meet the required standards before they are stocked or shipped. This entails conducting quality control checks before, during, and after-sales, with varying levels of investigation and testing, as well as handling any issues with products returned by our customers.

Jorge Serna: That's right. The Quality Control team plays a crucial role in our processes. They help us verify that products are up to standard, which is essential for both production and after-sales service. This collaboration ensures that any problems are promptly addressed and that our customers receive high-quality products.

Thank you both for sharing these insights. Your roles are clearly vital to the smooth operation of ZKTeco Europe and to ensure customer satisfaction.

Subscribe to our latest news & updates

Do you want to receive our latest Time Management, Access Control, and Software Solutions in your inbox? Subscribe now to ZKTeco Europe's Newsletter: